Dual-fuel firing in a new dimension

Flexible firing solution by SAACKE Marine Systems for M/S Viking Grace –the first time LNG fuel has been used for a passenger ship of this size

With a length of 214 meters and space for 2,800 passengers and 500 vehicles, the passenger ferry M/S Viking Grace operates daily on its route between Turku in Finland and Stockholm in Sweden. The special feature: The newbuilding, scheduled for completion in 2013, combines passenger comfort with a dual-fuel fuel concept, which, in addition to heavy fuel oil, also allows operation with marine diesel oil (MDO), marine gas oil (MGO) and, above all, natural gas - unique in the world for a ship of this size. The Viking Grace, built at the STX shipyard in Turku, thus benefits in terms of fuel flexibility and emission reduction. This increased energy efficiency is particularly important in view of the existing and, in the near future, even stricter regulations for Emission Control Areas (ECA) at sea.

"Viking Grace proves that natural gas can be used as a marine fuel every day. We are proud to contribute to this with our customized dual-fuel boiler plant".

- Dr. Katharina Boeck - Project Manager SAACKE Marine Systems

The world's first dual-fuel boiler system on a passenger ship of this size

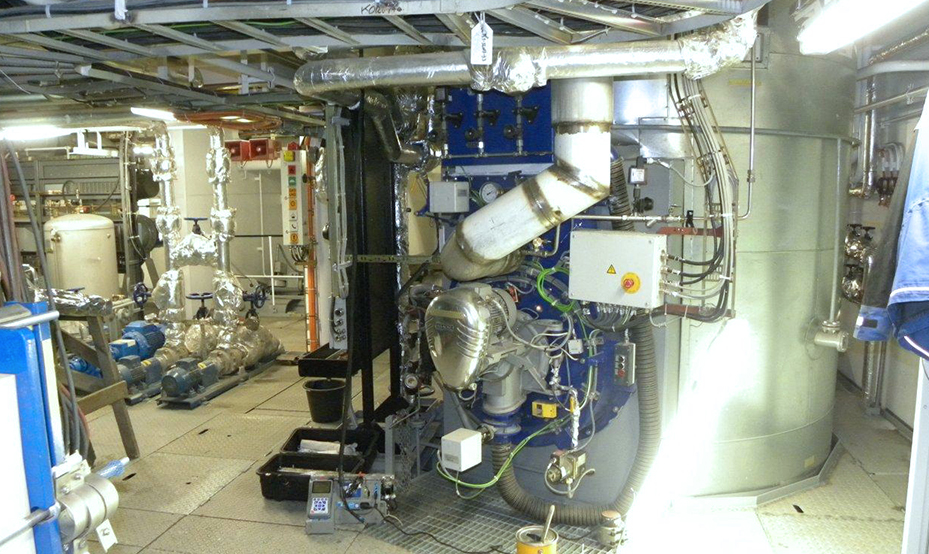

Due to its innovative character and the dimensions of the ship, the implementation was a special challenge for all project participants. SAACKE GmbH convinced with its dual-fuel solution consisting of two FMB-VM boiler plants with one SKVG 50* burner each, switchgears, fuel supply modules for gas and oil as well as four exhaust gas boilers for heat recovery. SAACKE accompanied the entire process chain from project planning and engineering to manufacturing and commissioning and also provides after-sales service. Various departments and locations of the international network of companies were involved - whether in Germany, Croatia, Sweden or the Netherlands.

All advantages at a glance

- Compliance with existing and planned emission regulations

- Independence from price developments of individual fuels through alternative operation with HFO, MDO, MGO and LNG

- No exhaust gas aftertreatment necessary, soot problems are eliminated

- High efficiency through SAACKE rotary atomizer technology

- Increased operational safety due to low gas pressures at the burner

- Low maintenance costs and long service life

The SAACKE solution in detail

The SAACKE FMB-VM is a steam boiler designed according to the water tube boiler principle, which is especially designed for ship operation. The SKVG* rotary atomizer is a duo-block burner with separate blower and is characterized by its flexibility with regard to fuel and installation conditions. The clean combustion of the gaseous fuel reduces emissions and the maintenance costs of both the boiler and the exhaust gas boiler.

For more than 80 years SAACKE has been developing industrial firing systems and today is one of the leading companies in this field worldwide. For decades we have also been applying our process engineering know-how to marine boilers and gas burners for marine applications. International system solutions from one source, core components from our own development and customized products - a complete package that also convinced the customer Viking Line.

*replaced by the ROTONOX GL

© SAACKE GmbH 2024