+49-421-64 95 0

info@saacke.com

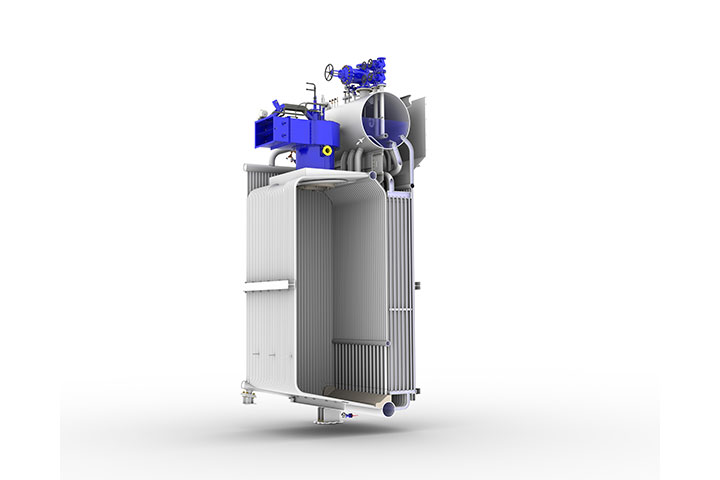

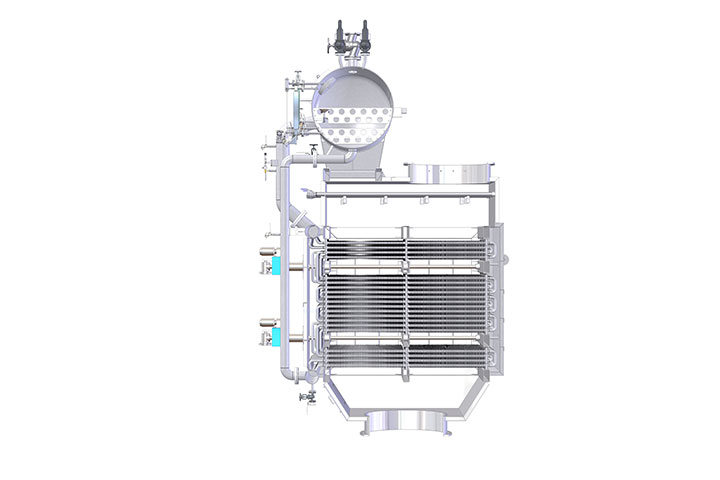

Fired marine boiler FMB-VS

- Vertical fired boiler

- Heat transfer is performed through the plate furnace

- Rifled plain smoke tubes

- Can be equipped with pin tubes on request

- The special spherical shape of the furnace top plate gives an increased stability against ship vibrations and protects this part of the boiler against partial overheating, because residues in the boiler water are led to the boiler bottom before they can accumulate on the furnace top plate

- Capacity range up to 5 t/h

- Design pressure up to 1,2 MPa

► Request technical data sheet

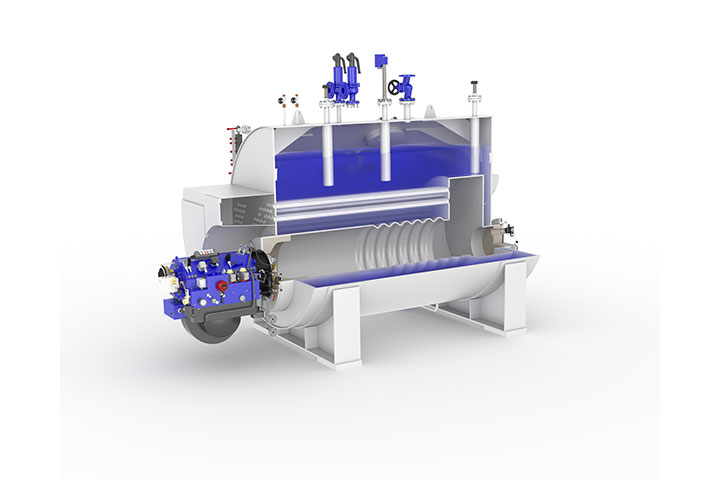

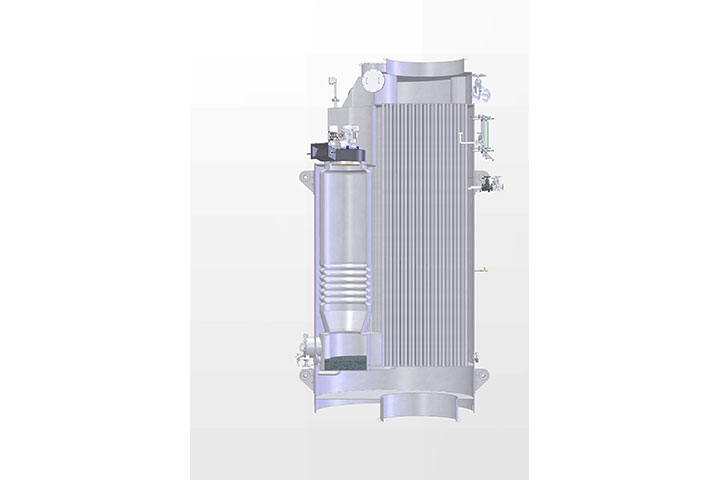

Fired marine boiler FMB-VM

- Water tube type steam boiler for medium power range

- The convection part can be equipped with rifled plain smoke tubes on request up to 16 t/h steam capacity

- The special spherical shape of the furnace top plate gives an increased stability against ship vibrations and protects this part of the boiler against partial overheating, because residues in the boiler water are led to the downcomer connections on the periphery of the drum before they can accumulate on the furnace top plate.

- Capacity range up to 6-25 t/h

- Design range up to 1,0 MPa

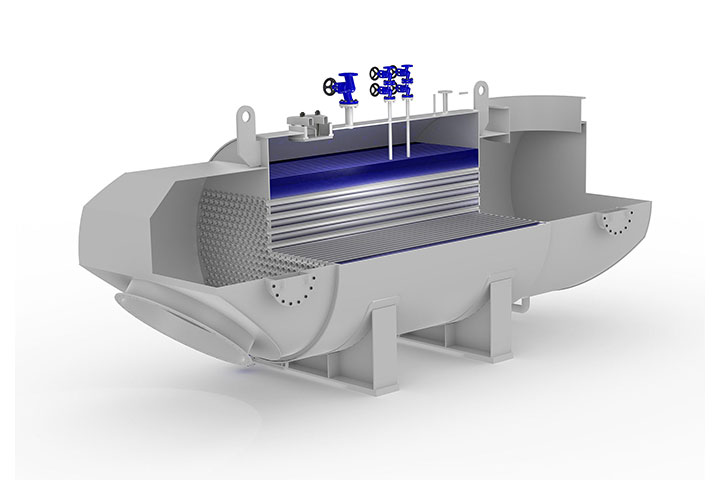

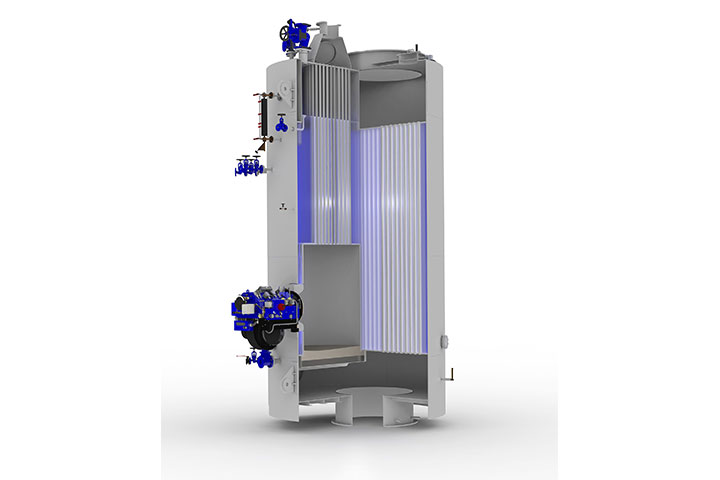

Fired marine boiler FMB-VL

- Water tube type steam boiler for medium to large power range

- The special spherical shape of the furnace top plate gives an increased stability against ship vibrations and protects this part of the boiler against partial overheating, because residues in the boiler water are led to the downcomer connections on the periphery of the drum before they can accumulate on the furnace top plate.

- Capacity range up to 14-45 t/h

- Design range up to 1,8 MPa

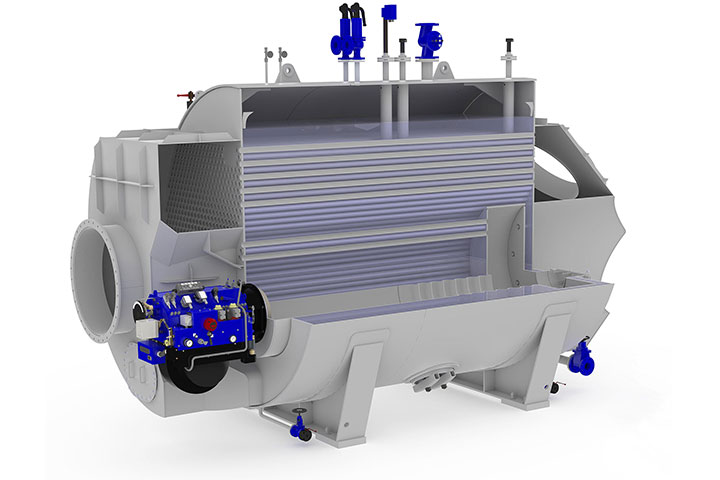

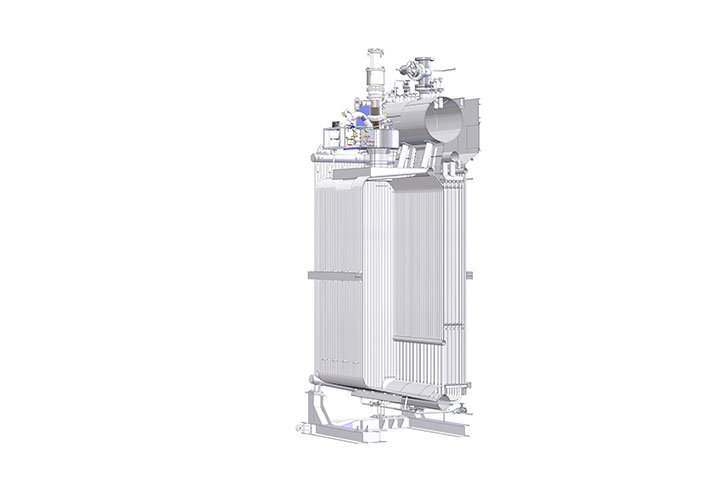

Fired marine boiler FMB-VD

- Top fired D-type boiler ..

- Due to the extended heating surface a very high efficiency is given under part-load conditions.

- Basically designed for the production of saturated steam, but can also be equipped with superheaters.

- Capacity range up to 30-110 t/h

- Design range up to bis 2,5 MPa (Can be adapted if requested by the customer)

Fired marine boiler FMB-VF-LONOX

- Vertical two-pass fired boiler

- Designed to incorporate proven Low NOx Combustion Systems

- Enables compliance with current and known future emission regulations and will allow boiler operation in ports worldwide.

- Minimum of burner refractory which significantly enhances operational reliability

- Combustion system can be equipped with water injection to improve solid particle emission levels

- Capacity range up to 18 t/h

- Design range up to 1,0 MPa

Smoke tube exhaust gas economizer/boiler EMB/EME-HST

- Horizontal smoke tube exhaust gas boiler respectively economiser

- Also fulfils partly the function of a silencer in the exhaust gas system

- Own steam space and therefore it works independently from other boilers in the system.

- Has to be connected to a fired boiler or a separate steam drum by means of forced circulation.

- Suitable for dry running in emergency case. .

- Capacity range on request

- Design pressure up to 2,2 MPa

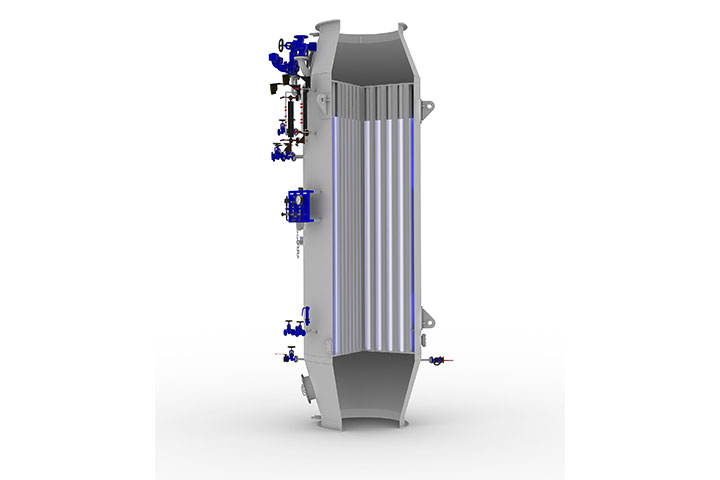

Smoke tube exhaust gas economizer/boiler EMB/EME-VST

- Vertical smoke tube exhaust gas boiler resp. economiser

- Fulfils partly the function of a silencer in the exhaust gas system.

- Own steam space and therefore it works independently from other boilers in the system.

- Has to be connected to a fired boiler or a separate steam drum by means of forced circulation.

- Suitable for dry running in emergency case

- Capacity range on request

- Design pressure up to 2,2 MPa

Smoke tube exhaust gas economizer/boiler EMB/EME-VFT

- Vertical exhaust gas economiser with forced circulation

- Fulfils the function of silencer in the exhaust gas system.

- Each module can be removed independently from the economiser casing for maintenance and repair.

- The external arrangement of the horizontal collectors allows to partly isolate and shutdown one or more modules

- Easy cleaning, the economiser is equipped with fixed water washing nozzles, soot blower connections and inspection doors.

- Suitable for dry running in emergency case.

- Capacity range on request

- Design pressure up to 2,2 MPa

Composite marine boiler CMB-VF-LONOX

- Low-emission 2-in-1 solution without compromising the steam output

- The vertical composite boiler also covers variable demands for steam

- For almost all ship types

- Saves on the need for an entire auxiliary boiler plant

- The boiler control is fully automatic

- Can be operated in a master-slave mode.

- Compatible with dual fuel applications

- Can be delivered with flue gas recirculation for emissions in the Ultra-Low NOX range

- Capacige CMB-VF-LONOX up to 13 t/h

Capacity range CMB-VF upt to 18 t/h - Design pressure up to 1,0 MPa

Composite marine boiler CMB-VS

- combined vertical exhaust gas and oil fired boiler

- The special spherical shape of the furnace top plate gives an increased stability against ship vibrations and protects this part of the boiler against partial overheating, because residues in the boiler water are led to the boiler bottom before they can accumulate on the furnace top plate.

- Capacity oil-fired range up to bis 5 t/h

Capacity flue gas range as needed - Design pressure up to 1,2 MPa

Composite marine boiler CMB-HF

- combined horizontal exhaust gas and three-pass oil fired boiler

- Smoke tubes and the furnace can be easily accessed for cleaning and maintenance purposes through the reverse chamber doors.

- Capacity oil-fired range up to 10 t/h

Capacity flue gas range as needed - Design pressure up to 1,2 MPa

Fired marine water heater VMW-VD

- Top fired D-type water heater

- Due to the extended heating surface a very high efficiency is given under part-load conditions

- Convection part can be cleaned by means of soot blowers.

- Capacity range 20-75 MW

- Design pressure up to 2,5 MPa (Can be adapted if requested by the customer)

© SAACKE GmbH 2024