Alternative Fuels – Molasses combustion in Brazil

Pilot plant for IMCOPA in the Brazilian state of Paraná

By-products turned into heat and fertilizer

Not only are by-products in industrial processes often not exploited, but they are also a real environmental problem, like the case of liquid vinasse (also spent wash dunder) and molasses. The Araucária pilot plant in the Brazilian state of Paraná shows that these problematic substances can be profitably utilized, thus providing relief for the company’s budget and the environment. Brazil is the world’s biggest supplier of biogenic fuels: sugar cane and soy, from which bioethanol and soybean oil are extracted on site, are grown on enormous areas. In addition to these valuable sources of energy, however, molasses and vinasse are also created as undesired by-products during processing.

Both contain up to 50 % water and have a low heating value of max. 10 MJ/kg. Because of their high proportion of organic substances, vinasse and molasses have been disposed of as liquid compost on surrounding areas up to now. This made them a double environmental problem as the organic components pollute the air, and the nitrogen they contain contaminates the groundwater. Moreover, molasses is generated in large quantities: the plant presented processes 650 tons a day.

All advantages at a glance

- High degree of availability and robust technology

- Main fuel at zero cost

- Savings of over 70 % supporting fuel

- Ash serves as fertilizer

- Large control range

- Short project period

- Alternative fuels: soybean oil, animal fat

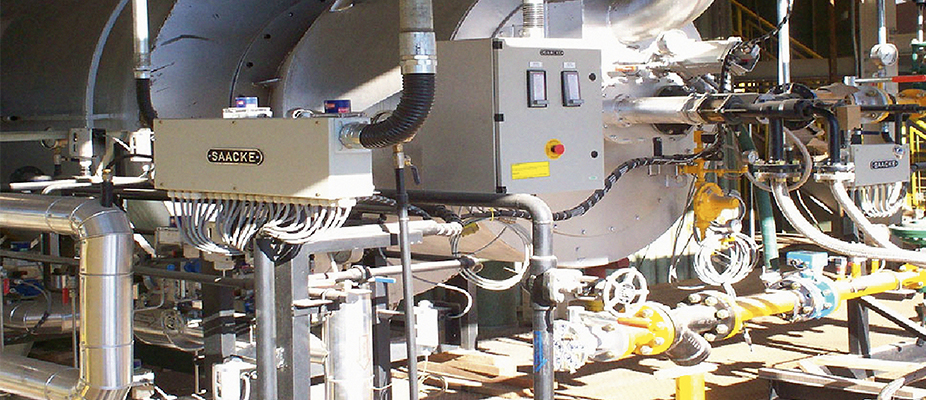

The SAACKE solution in detail

The core of the combustion process consists of two SAACKE SSB-LCL burners with an output of 26 MW each that fire a steam boiler at 60 t/h and burn the by-products stably and secure. Fuel preparation is also demanding since the highly viscous substances contain sugar, have a corrosive effect and crystallize at high temperatures.

The project, developed within a short time, encompasses the adapted series burners as well as fuel supply and preparation, thus guaranteeing high availability and reliable operation. In both cases natural gas serves as starting and supporting fuel. Its share was minimized and accounts for less than 30 % of the total amount of fuel.

Vinasse and molasses contain little energy, but a lot of water and ash. The boiler is adapted to the high ash content: it is collected and separated in a controlled manner during operation. Because the fuel is of biogenic origin, this ash can be used as fertilizer in agriculture. Besides the aspect of disposal and energy extraction, the production of fertilizer further improves the environmental balance and enhances its profitability.

SSB-LCL: Expert for low heating values

The SAACKE SSB swirl burners used are adapted for this application. They are based on the SSB swirl burner that has proven effective for industrial and power station purposes for years with several hundred units installed. Its design is suitable in principle for all fuels and generates a broad and short flame. Because of the pronounced swirling of the main air, the flame is exceptionally stable and offers a large control range. The SSB is equipped with a special muffle for liquids with a low heating value. This muffle stabilizes the flame before it goes over to the boiler. The SSB adapted for Araucária can handle more than just the main fuels molasses and vinasse and is also equipped for operation with soybean oil, animal fat and natural gas. Soybean oil and animal fat are prepared like a standard fuel and conveyed to the combustion chamber with the oil gun. The two additional fuels increase the autonomy of the plant and, besides the cost advantages, provide further relief for the environment.

Combustion of molasses and vinasse is a classic win-win situation: even though the application requires high-tech equipment and precise adaptation to the individual plan, it permits enormous cost savings because over 70 % of the fossil fuel is replaced. Furthermore, the environment profits again as valuable fertilizer is created from the problematic substances.

MORE INDUSTRY REFERENCES

- Plant modernization - Conversion from mixed firing to natural gas in specialty chemicals

- Alternative Fuels - Lean gas

- Water tube boilers - Modernization of a refinery in Bulgaria

- Shell boilers - Combined heat and power system incl. gas turbine exhaust gas burner and control technology for food production

- Burner / Steam pressure atomizer - Equipment of a district heating plant near Vienna with burners for low NOx emission and flexible operation

- Drying processes - Pulverized fuels and biogas for drying sugar beet cossettes

© SAACKE GmbH 2024