GTA auxiliary combustion systems

Use of gas turbine flue gas in a reasonable way

Generating electricity with a gas turbine and steam with its hot exhaust gas is environmentally friendly and efficient - in principle. In practice, however, such combined processes only achieve a fuel efficiency of around 75% and leave considerable reserves unused. A GTA auxiliary combustion system between turbine and waste heat boiler utilizes the residual oxygen contained in the turbine exhaust gas and improves the fuel efficiency of the plant to over 96%.

The SAACKE portfolio includes:

- Burners and combustion systems for waste heat and water tube boilers and insulated combustion chambers with downstream exhaust gas heat exchangers

- Burners and combustion systems for heating turbine exhaust gases in power plants and for heating process air in drying plants

- Tailor-made arrangements/constructions according to customer requirements

- Use of proven standard burners for gaseous and liquid fuels

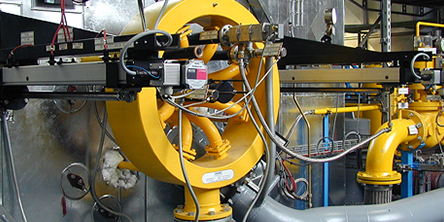

In principle, both surface burners (GDG series) and steam pressure atomizer burners (e.g. DDZG A and DDZG GT series) are available for GTA auxiliary combustion systems in various configurations that can be perfectly adapted to any system. Thus, neither high GTA temperatures of up to 650°C nor particularly low pressures of only a few mbar behind the turbine are an obstacle to using the valuable energy in the exhaust gas. They are always individually tailored to the gas turbine system and make efficient use of even the smallest installation space.

In addition to combined operation with turbine and burner simultaneously, individual operation of the two components is also possible. In each case, a sophisticated control system ensures the optimum operating point of the burner, complete burnout and lowest emission values. Whether simple emergency firing or hard continuous operation with 4 burners and 160 MW, GTA technology from SAACKE always guarantees highest availability and a very long service life.

© SAACKE GmbH 2024