The main items of consideration for combustion plants are fuel flow, atomization, control response and emission values. All of these aspects are important. However, they are inseparably linked with the basic element of clean firing, which is frequently left out of consideration: The air required for combustion. Only an individually dimensioned combustion air supply will ensure a wide control range, stable combustion and the best emission values. SAACKE engineers have always placed great emphasis on this seemingly secondary aspect, creating the basis of efficient combustion with perfectly adapted fans, air channels and controllers.

In addition to the installation altitude, the arrangement of the fan and the length of the air channel, combustion systems differ mainly in the furnace back pressure. Along with the volume flow, this back pressure is the determining dimension in the design of the impeller, casing and drive motor. SAACKE radial fans have precisely balanced high-performance wheels and exactly adjusted motor power, even in the partial load range. This gives them a very high level of efficiency. They are therefore perfectly suited for use of speed control systems, which allows them to save even more electrical current.

The combination with a speed control system is always worth considering when the burner is not constantly operated at full load. Normally in this scenario, much valuable energy is wasted by the air control dampers. Not so with fans that have SAACKE speed control: The fan speed is then adjusted with the air requirement, which considerably reduces both power consumption and noise emission.

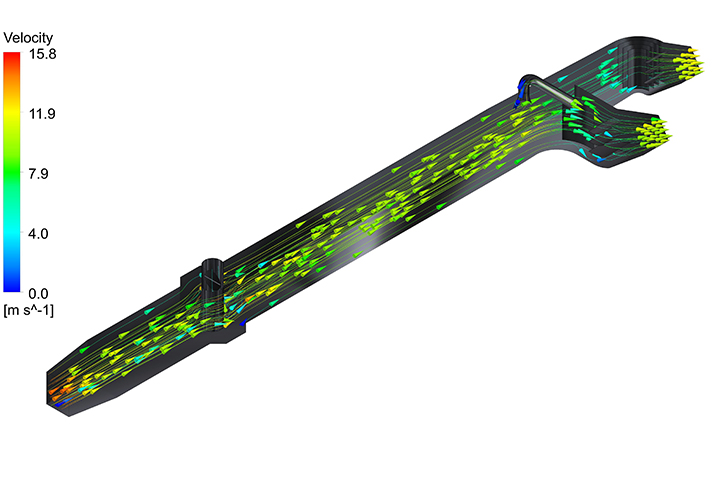

In addition to the fan, the air channels also have a great effect on the quality of the air flow and the amount of pressure and energy loss. Careful individual planning of small details quickly makes a noticeable difference in this case – and also reduces operating costs. The same applies not only to plants with one burner per fan, but also to more complex firing systems in which one fan supplies air to multiple burners.

With decades of experience in designing channels, bends, widenings and branchings, SAACKE ensures that every combustion plant is reliably over its entire control range and that the air supply saves energy. Then speed control and air channels can again become matters of secondary concern although they are the dependable cornerstones of every combustion plant. It may not be exciting to hear that all the components are long maintenance with a long service life, but it is very reassuring.

- Individual planning for stable combustion and perfect burnout

- High-performance radial fan with high efficiency

- Speed control for lowest power consumption levels in partial load

- Perfectly adjusted air channel

- Optimized bends, widenings and branchings

- Decades of experience in engineering

© SAACKE GmbH 2024