Shell boilers - Combined heat and power system incl. gas turbine exhaust gas burner and control technology for food production

Power, heat or steam effectively from one source

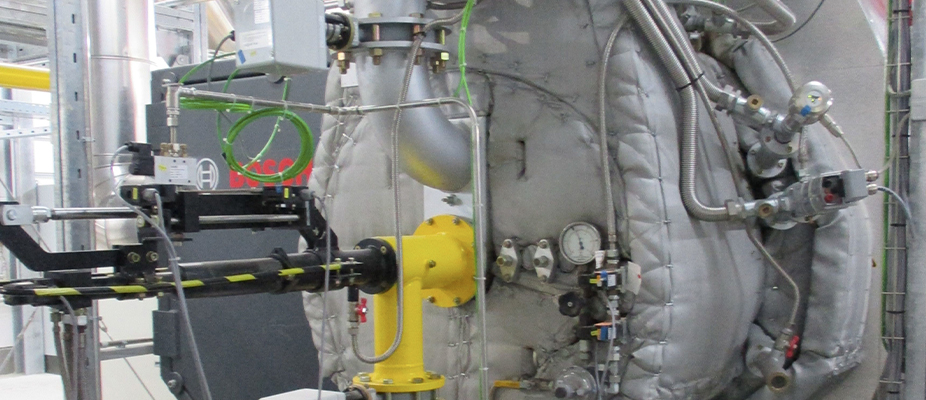

Interquell GmbH requires process steam for the production of food, such as baby food and cereals, at its site in Großaitingen, Swabia. In order to increase efficiency and to save costs, the food manufacturer decided to have a SAACKE micro-CHP system installed by the plant manufacturer Lausser. The combination of micro gas turbine, gas turbine exhaust gas burner and steam boiler was chosen because conventional CHP plants cannot guarantee the requirements.

"The innovative SAACKE solution is not only demonstrated in active operation - the plant was also awarded the LEW Innovation Prize 2013".

- Georg Müller, Managing Director, Interquell GmbH

Increased efficiency by using waste heat from power generation

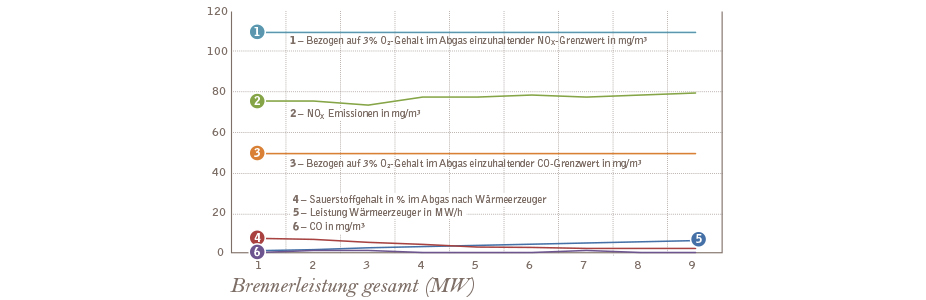

The heat generation by the SAACKE DDZG-GTM exhaust gas burner is preceded by a micro gas turbine, which produces 1,460 MWh electrical energy per year for the Großaitingen site. By using the hot turbine exhaust gases as combustion air in the gas turbine-exhaust gas burner, the overall efficiency increases up to 97 %. Supplemented by a flue gas condensing boiler, the overall energy efficiency is significantly increased. The challenges of this highly efficient solution also included effective time management and comprehensive service. Downtimes had to be kept to a minimum so as not to interrupt ongoing operations.

All advantages at a glance

- Long maintenance intervals for turbine and burner

- Low emission values far below legal limits

- Can be used on existing and new systems

- High energy efficiency through combination of micro gas turbine and gas turbine exhaust gas burner

- Efficient turbine utilization through variable air surpluses at DDZG-GTM

- High availability through uninterrupted change of operating mode

The project was funded by the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety, the Federal Environment Agency and the Kreditanstalt für Wiederaufbau (KfW).

The DDZG-GTM supplied can be delivered as a combination burner for natural gas and fuel oil. For fuel oil, no additional atomizing medium is necessary. On the burner side, a full fresh air operation, a GTA operation and a waste heat operation (heat retention operation) are available without restriction - always in connection with lowest emission values. The burner can be operated safely and stably with both high and low excess air (Lambda 2.1 to 1.1). The micro gas turbine can be provided by the customer or supplied by SAACKE. The main scope of supply included the delivery of the burner, the fuel supply for natural gas and fuel oil, the blower for fresh and secondary air supply, the installation of measuring and monitoring devices as well as the control switchgear and control circuits. The SAACKE service includes assembly, commissioning and trial operation as well as a 24-hour stand-by service.

The combination of micro gas turbine and the gas turbine exhaust gas burner DDZG-GTM is the secret of the success of the SAACKE micro-CHP system. A high overall efficiency, the generation of electrical energy and the efficient and low-emission combustion of turbine exhaust gases help to save costs and generate process steam economically. In the meantime, this has also been tested and confirmed by external experts.

More industry references

- Plant modernization - Conversion from mixed firing to natural gas in specialty chemicals

- Alternative Fuels - Lean gas

- Alternative Fuels – Molasses combustion in Brazil

- Water tube boilers - Modernization of a refinery in Bulgaria

- Burner / Steam pressure atomizer - Equipment of a district heating plant near Vienna with burners for low NOx emission and flexible operation

- Drying processes - Pulverized fuels and biogas for drying sugar beet cossettes

© SAACKE GmbH 2024