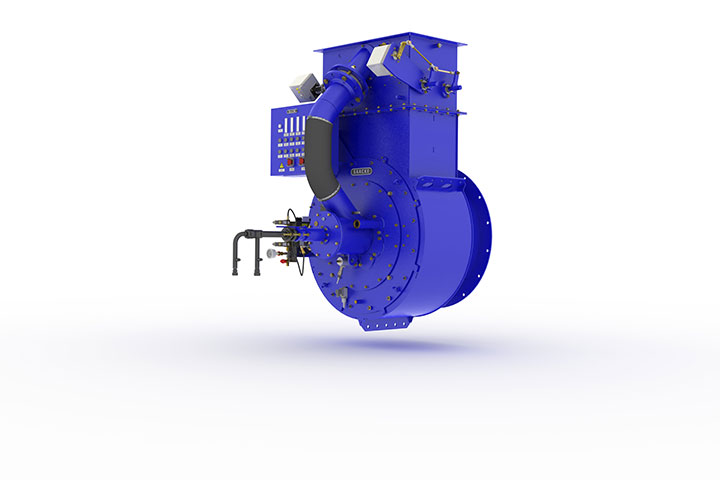

The SAACKE steam pressure atomizer is designed for firing medium and large sized water tube boilers such as auxiliary and main boilers for tankers and FPSOs.

The unique SAACKE design features staged combustion air supply and distribution. This allows a high control range and ensures complete combustion, resulting in low O2 values even when operating on low load. At the same time, a very stable flame over the whole load range is given. On account of its highly versatile flame geometry, the DDZ-M burner is equally suitable for side fired and top fired boilers. The fuel-air ratio is controlled by an electronic compound regulator in combination with a PLC combustion controller. A mechanical compound regulator can be supplied on demand. For FPSOs and LNG carrier applications this burner is available as a combined oil and gas burner, of type DDZG.

- Liquid fuels

Heavy Fuel Oil up to 700 cSt/50°C

Marine Diesel Oil

Marine Gas Oil - Gaseous fuels

Natural gas standard and all others on demand, e.g. natural gas from well - Capacity range 8,5 – 37 MW

- Control range

1:7 for burners up to 13,5 MW

1:10 for burners up to 13,5 - 21 MW

1:15 for burners > 21 MW

► Request technical data sheet

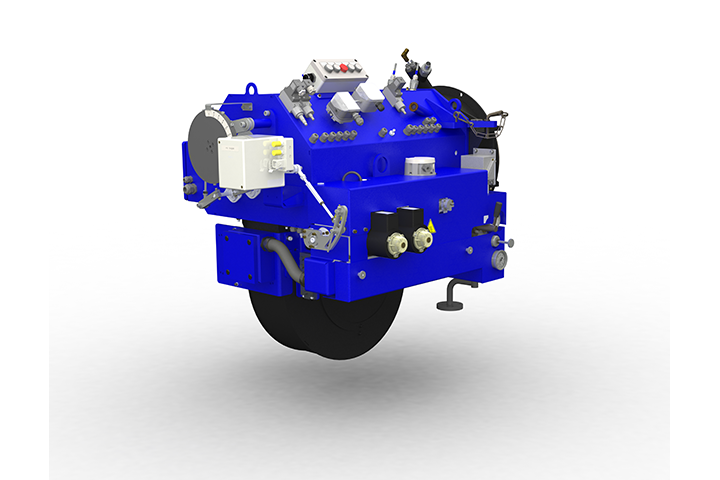

the compact and extremely robust SKVJG-M Monoblock Rotary Cup Burner allows the use of the high viscosity fuels common in the industry. The larger control range of the rotary cup compared to other technologies increases the maximum efficiency of the combustion system. Depending on the fuel, the SKVJG-M is available as a burner for purely liquid fuels or as a combined burner for gaseous fuels. Simultaneous operation of oil and gas for the thermal utilisation of excess residual materials during gas freeing and gas up as well as direct thermal utilisation of boil-off gas is possible.

Easy installation, handling and maintenance distinguish the SKVJG-M, making it a durable and profitable investment for new installations or retrofits. In addition, the burner has a sophisticated safety concept. This allows emergency operation even if the automatic burner control unit fails thanks to the mechanical fuel/air ratio control.

- Fuels

Heavy fuel oil up to 700 cSt at 50 °C

Marine diesel oil (MDO)

Marine gas oil (MGO)

Natural gas

LPG and LNG (in gas phase) - Capacity range 0,95 – 3 MW

- Control range max. 1:7 (depending on size)

► Request technical data sheet

© SAACKE GmbH 2024