Water tube boilers - Modernization of a refinery in Bulgaria

Emissions significantly lower than specified for efficient refinery gas utilization

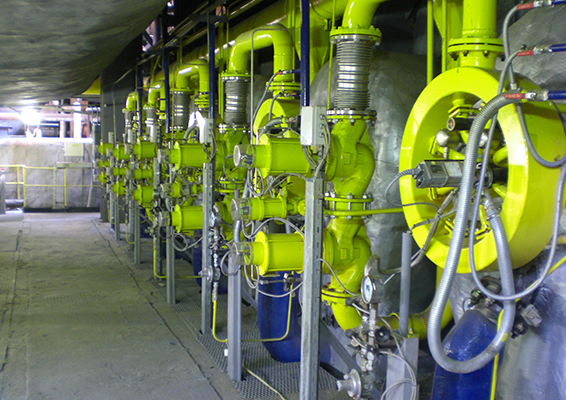

On Bulgaria's Black Sea coast, the Russian oil company Lukoil operates the largest refinery in Southeast Europe. During the refining of crude oil, refinery gas is a by-product of the process, which has not been used efficiently so far. The steam produced in water-tube boilers is used to generate electricity or as process steam according to the principle of combined heat and power generation. Until now, the boilers have operated inefficiently and achieved emission values around 350 mg/m3 NOx.

A particular challenge: Due to the burner arrangement, a simple replacement with low NOx burners would not have achieved a significant improvement in these values.

"All work was done with high professionalism, quality and in the shortest possible time. The modernization increased the boiler efficiency by more than 8 % at all load points. At the same time, NOx emissions were halved."

- A. A. Belov, Lukoil, manager of the Burgas plant

Innovative combustion and process engineering

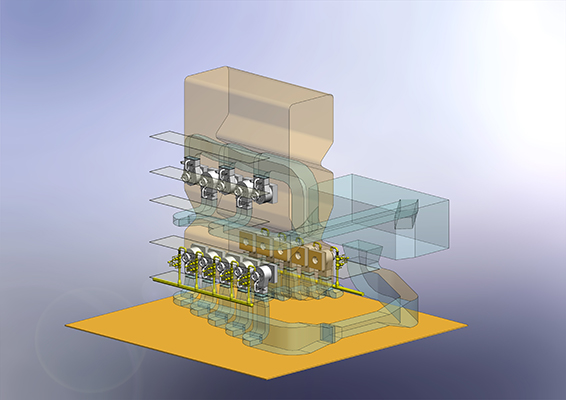

SAACKE developed an intelligent modernization concept for the combustion plant with the help of ultra-modern CFD (Computational Fluid Dynamics) flow simulations. This concept could be optimally integrated into the existing infrastructure and led to a very short rebuilding phase as well as significantly reduced rebuilding costs.

All advantages at a glance

- Minimal downtime and conversion costs through optimal integration into existing infrastructure

- Time and resource-saving development using CFD simulations

- Increasing efficiency and reducing NOx emissions

- Professional project management, fast delivery and smooth commissioning

- Robust, low-maintenance firing system with maximum availability and easy operation

- Modernized orientation for future investments and environmental requirements

- Reliable maintenance service even after commissioning

The SAACKE solution in detail

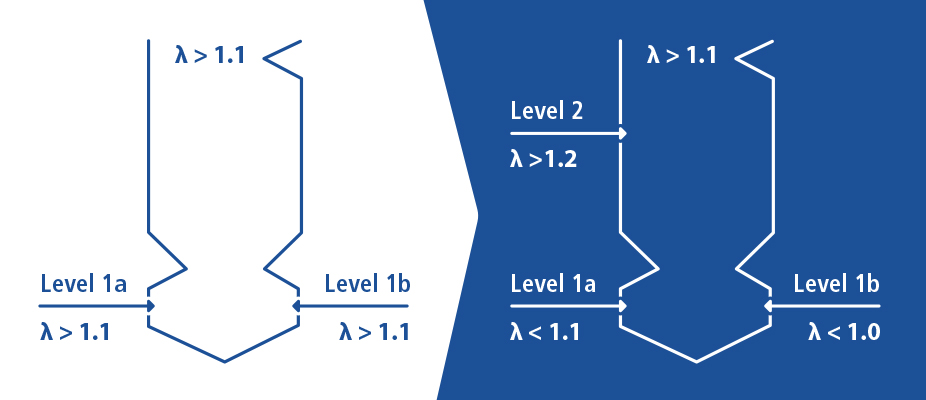

The 15 new DDG burners have been arranged on two levels in such a way that staggered combustion in the combustion chamber results in the lowest emission values below the European NOx limits. The burners of the two lower levels are operated understoichiometrically, those of the upper level overstoichiometrically. In the lower level, the refinery gas is now also used thermally. The intelligent design of the plant ensures a high availability with low maintenance requirements. Thanks to an optimal combustion air flow, which was calculated by means of CFD simulations and significantly reduces the pressure loss in the air duct, the customer could continue to use two existing blowers and thus save about 10 % of the investment volume. The SAACKE project management from one source and products "Made in Bremen" guaranteed a very short implementation phase and provided planning security for the customer. The flexibility of the plant and the efficient incineration technology allow a quick payback for the operator and furthermore relieve the environment.

SAACKE solves complex challenges in the modernization of water-tube boilers with high-end combustion technologies and engineering tailored to the customer's individual needs. From planning to smooth commissioning and maintenance, SAACKE is your partner for combustion plants as well as complete, optimally coordinated plant systems.

MORE INDUSTRY REFERENCES

- Plant modernization - Conversion from mixed firing to natural gas in specialty chemicals

- Alternative Fuels - Lean gas

- Alternative Fuels – Molasses combustion in Brazil

- Shell boilers - Combined heat and power system incl. gas turbine exhaust gas burner and control technology for food production

- Burner / Steam pressure atomizer - Equipment of a district heating plant near Vienna with burners for low NOx emission and flexible operation

- Drying processes - Pulverized fuels and biogas for drying sugar beet cossettes

© SAACKE GmbH 2024