Transporting liquefied natural gas by sea is always a question of safety. Gas Combustion Units (GCUs) enable this safe transport by burning excess Boil-Off gas completely and with maximum availability. For this reason, Hudong-Zhonghua Shipbuilding (Group) Co, Ltd. commissioned SAACKE GmbH from Bremen to manufacture and supply GCUs with a plant capacity of 5.2 tons of gas per hour each for their six new LNG tankers. Since the end of 2015 they have been operating between North Australia and China for the ship owner China Shipping LNG Investment Co, Ltd.

"The safe sea transport of LNG is a top priority for our customer. Therefore, the SAACKE solution with 100 % free flow was convincing right from the start".

- Andreas von Minden, SAACKE Sales Manager Off shore Application

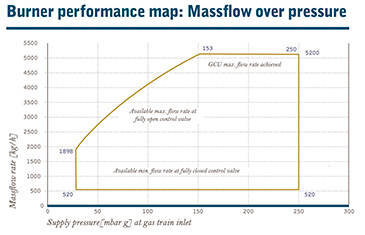

Safe firing at low pressure

This is already the second time that Hudong-Zhonghua uses SAACKE's know-how, but the first order where a GCU for operation under 100 % FreeFlow conditions was requested. As a rule, excess Boil-Off gas is fed to the consumers by means of a compressor and with 3 to 4 bar pressure. Gas no longer required for the ship's engines is burned via the GCU. However, there is a risk that the compressor will fail and safety risks arise due to the increasing pressure in the tank. In SAACKE's 100 % free-flow solution, the boil-off gas is completely combusted without a compressor and already at a pressure of 0.15 bar - the gas pressure is thus much lower and the entire system is safer than other systems. This was also the main reason for the customer to choose SAACKE GCUs.

All advantages at a glance

- Rainproof design to prevent corrosion and wear of the GCU components, especially the burner and the combustion chamber bottom

- The inner lining of the combustion chamber gives the GCU a cold and therefore strong structure

- High excess air ensures a low flame temperature and thus low heat radiation and low NOX emissions

- No contact between the flame and the combustion chamber walls in rough seas and therefore no wear and tear and no damage to the combustion chamber

- No belt-driven blowers and therefore low maintenance costs

- Oil-fired pilot burner ensures continuous operation when required under special conditions

- Controlled fuel/air ratio ensures safe combustion and low emissions

- Internal parts such as combustion chamber and burner can be removed or replaced via the chimney shaft for maintenance

- The space between combustion chamber and outer shell is accessible and allows easy inspections

- All gases are completely burned

- 100 % free flow possible

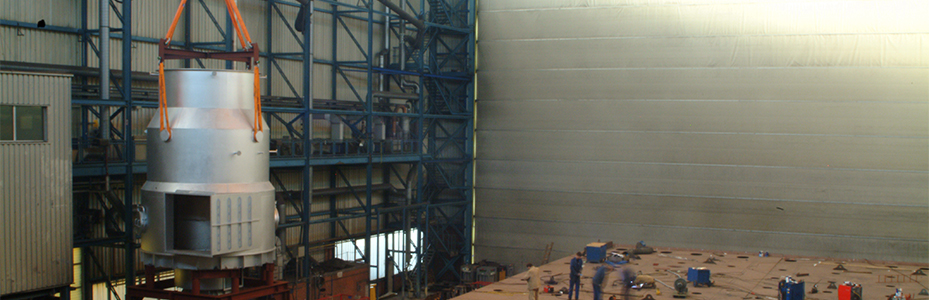

The GCU combines the SAACKE Low Emission Swirl Burner SSB 500 with an air-cooled steel combustion chamber. All components are built so compactly that the 15-meter high and 36-ton plant can be placed in the area of the chimney and saves valuable installation space in the ship. The pre- and post-combustion chamber as well as the burner and the gas fittings were manufactured in Bremen, the outer shell was manufactured in our own production facility at the Chinese SAACKE site in Qingdao. Here the individual GCU components were also assembled and implemented until they were finally installed in the ship directly on site at the shipyard in Shanghai.

One thing is clear: LNG transports will increase significantly in the coming years. This makes the safe and environmentally friendly burning of boil-off gases at sea all the more important. SAACKE already introduced the Gas Combustion Unit as a completely new development to the market in 2002. Since then, this core competence has been continuously expanded - the most recent example: the 100% free-flow solution. The success proves the company right: Up to now about 80 SAACKE GCUs have been installed on ships worldwide.

© SAACKE GmbH 2024