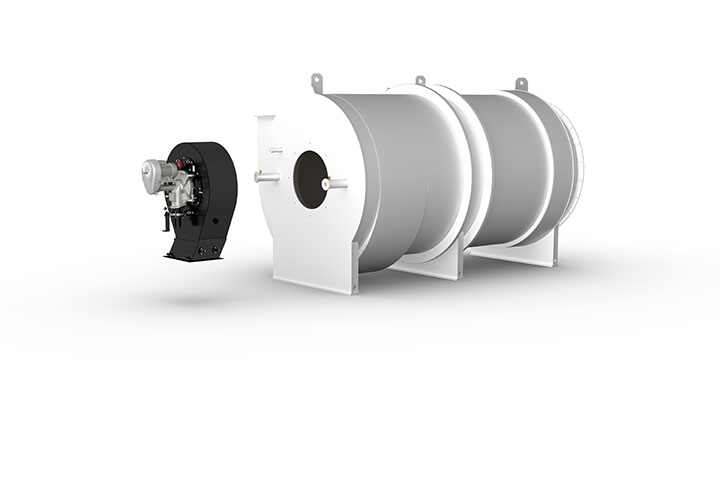

If space is limited, the hot gas generators of the CCS-HTcompact series are often the first choice. The CCS-HTcompact consists of a double steel shell, lined with refractory bricks inside. Optimised for natural gas combustion systems, a SAACKE SSB-G is used as the burner, which generates a moderate combustion chamber temperature thanks to a high excess of air, guarantees perfect burnout and thus very low emissions.

Its high control range also allows adaptation to all application profiles. In combination with a sophisticated furnace geometry in the combustion chamber, an extremely homogeneous temperature profile between 600 and 1,000°C is produced at the outlet of the hot gas generator. The mixed air enters the double shell tangentially, flows between the inner and outer shell and is mixed with the hot gas with a high mixing pulse at the end of the combustion chamber. Thus it cools the steel shell, reduces radiation losses and simultaneously precisely adjusts the temperature of the hot gas. Thanks to the compact dimensions, the total weight of the hot gas generator is reduced. Taking customer requirements into account in conjunction with SAACKE engineering, the CCS-HTcompact impresses with its flexible range of applications, performance and economy.

- Low weight and extremely compact dimensions

- Natural gas (special gases and low calorific fuels on request)

- Variable mixed gas / mixed air quantity

- Wide control range

- Robust, durable construction

- Homogeneous temperature profile

- Low radiation losses

- Highly efficient SAACKE combustion technology

- State-of-the-art control technology with the se@vis combustion manager

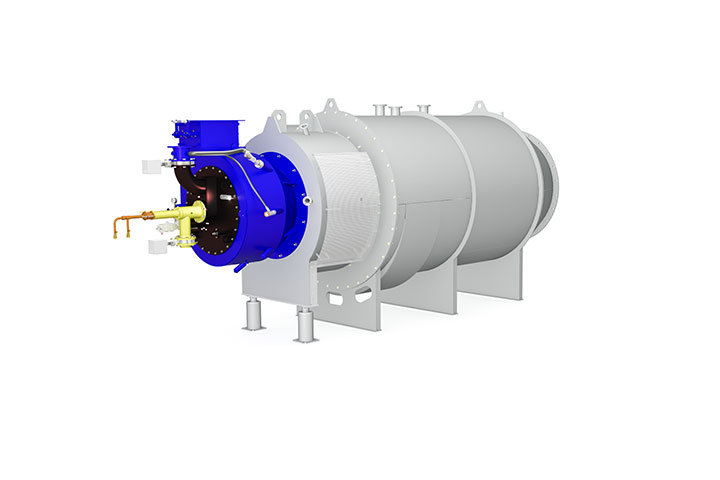

With the CCS-HT combustion chamber series, SAACKE offers standardized hot gas generators in a wide load range. Proven thousands of times in real applications, they are suitable for all standard fuels as well as numerous special fuels and can be used to operate any SAACKE burner in almost any installation position.

Regardless of the size, all CCS-HT combustion chambers consist of a stable double shell with fireproof refractory brickwork. The mixed gas enters the double shell tangentially, flows between the inner and outer shell and is mixed together with the hot gas at the end of the combustion chamber. The gas cools down the steel shell in this manner, and also serves, by varying the quantity, as a correction mechanism to maintain a precise temperature at the output of the hot gas generator.

The temperature profile at the output of the combustion chamber is also especially homogenous due to the sophisticated design. The mixed gas is guided by free flowing for the best results, thus guaranteeing a high level of efficiency for downstream processes.

All burners are operated with a high air excess of 60-80%, providing optimum burnout with an especially wide control range. The furnace temperature of about 1400°C is possible because of the high air excess, which also reduces wear on materials, and the very low emission level. Depending on the fuel and firing capacity, the hot gas temperature ranges between 600 and 1000°C. The refractory brickwork of the CCS-HT is relatively thin compared to other designs due to the cooled double shell. This allows for fast, precise control with very short startup times.

- Outlet temperatures from 600 - 1000°C

- Can be operated with any burner type

- Suitable for all standard fuels, low-calorific liquids and gases as well as numerous pulverized fuels

- Large control range with very low emission values

- Short startup times and precise control

- Long maintenance intervals and service life

► Request technical data sheet

Combustion chambers with refractory brickwork reach their limits as soon as increased heat flow requirements are placed on the downstream process (for example in intermittent operation, if the temperature changes quickly or with short startup and shut-down times). SAACKE offers a series of proven and cost-effective solutions with various designs of all-steel combustion chambers. Because of the low pressure loss on the mixed gas side, the CCS-LT combustion chamber series is ideal for large volume flows of mixed gas and therefore permits low hot gas outlet temperatures.

An SSB series burner forms the core of the combustion system: Its gas or oil flame is not only very stable, but also extremely short. Yet the outer dimensions of the hot gas generator are still compact and can be mounted in the plant in any installation position.

The mixed gas enters the double shell tangentially, cools the furnace and is mixed evenly with the hot gases emerging from the nozzles at the furnace end. The temperature profile is especially balanced at this point and is extraordinarily homogeneous with +/- 20°C across the entire window. Pressure loss is extremely low overall, thus allowing for large volume flows, very low outlet temperatures and economical mixed gas fans.

- Outlet temperature 400°C to 650°C

- Fast control response

- Short startup and shut-down times

- Very homogeneous temperature profile at the outlet

- Low weight and small dimensions

- Low pressure loss allows for economical fans

© SAACKE GmbH 2024