Reference projects Marine Systems

Safe, environmentally friendly and energy-efficient firing systems for seagoing vessels, offshore installations and LNG tankers. Development, design and construction of new plants as well as retrofitting and modernization/retrofit of existing plants. Our portfolio ranges from naval boiler plants and systems to exhaust gas purification/scrubber and gas combustion units (GCU) and complete plants for the offshore sector. Learn more about us through our reference projects.

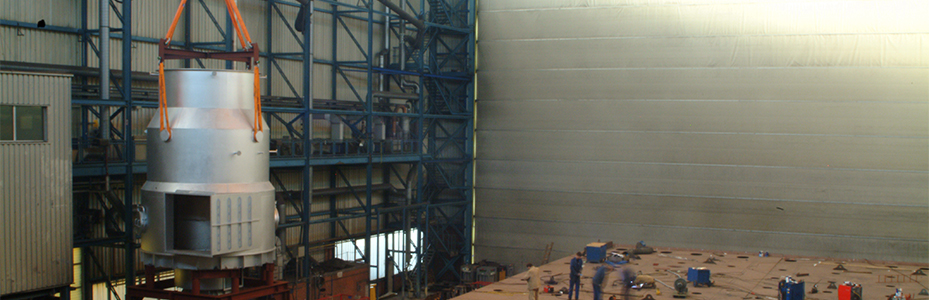

Transporting liquefied natural gas by sea is always a question of safety. Gas Combustion Units (GCUs) enable this safe transport by burning excess Boil-Off gas completely and with maximum availability. For this reason, Hudong-Zhonghua Shipbuilding (Group) Co, Ltd. contracted Bremen-based SAACKE GmbH to manufacture and supply GCUs with a plant capacity of 5.2 tons of gas per hour each for their six new LNG tankers.

► More about this project

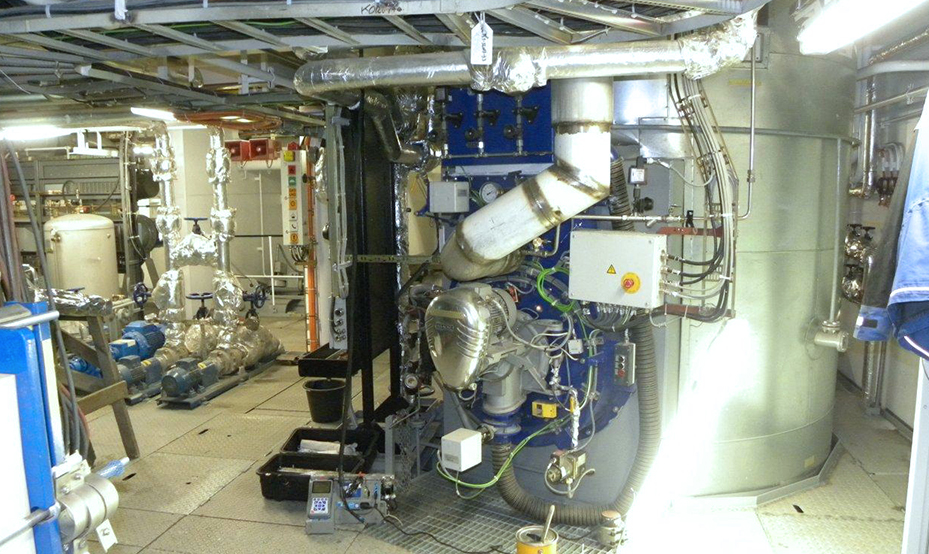

With a length of 214 meters and space for 2,800 passengers and 500 vehicles, the passenger ferry M/S Viking Grace operates daily on its route between Turku in Finland and Stockholm in Sweden. The special feature: The newbuilding, scheduled for completion in 2013, combines passenger comfort with a dual-fuel fuel concept, which, in addition to heavy fuel oil, also allows operation with marine diesel oil (MDO), marine gas oil (MGO) and, above all, natural gas - unique in the world for a ship of this size.

► More about this project

The International Maritime Organization (IMO) has set itself the clear target of reducing the sulfur content of ship exhaust gases. Since 2015, for example, limits of 0.1 percent have applied to the North Sea and Baltic Sea. Guidelines that cannot be met with unfiltered heavy oil emissions. This was also recognized by the Bremen-based shipping company Carl Büttner, specialized in the operation of oil and chemical tankers. They commissioned SAACKE GmbH to implement an efficient exhaust gas cleaning system on the four-year-old and 140-meter long tanker MT Levana.

► More about this project

Until late summer 2016, electricity for Malta's more than 400,000 inhabitants was still generated by oil-fired power plants. With the aim of generating electricity with lower emissions and greater efficiency, ElectroGas Malta Ltd commissioned the Malaysian-based offshore energy and service provider Bumi Armada Berhad to convert an LNG tanker into a Floating Storage Unit (FSU). Within the scope of this major project Bumi Armada ordered two SAACKE DType boilers FMB-VD with a capacity of 20 tons superheated steam per hour each. Due to the low-NOX design they guarantee lowest emission values of 100 mg/m3 in gas operation and 450 mg/m3 in oil operation.

► More about this project

110 kilometers off the Brazilian coast and up to 1,400 meters deep - the Papa Terra oil production area near Rio de Janeiro. 350 million barrels of oil are to be produced here by around 2030. For this purpose, Bergesen Worldwide Offshore (BWO) converted the supertanker BW Nisa into the FPSO unit P-63 together with SAACKE.

► More about this project

© SAACKE GmbH 2024