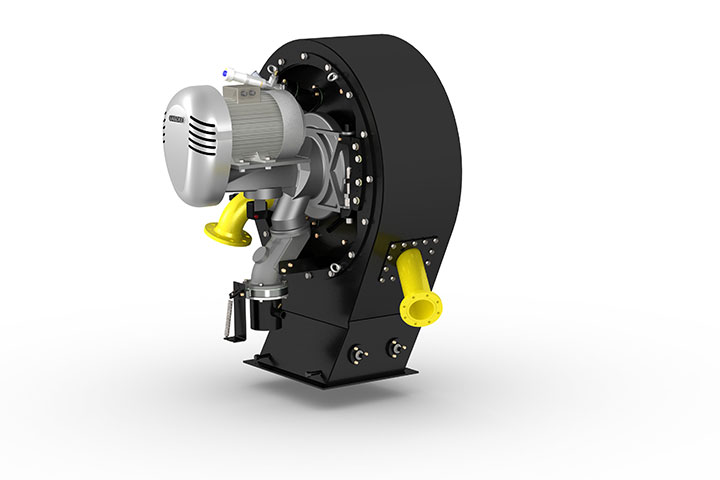

Use instead of waste. The ROTONOX GL uses rotary atomiser technology to burn a wide range of gaseous and highly viscous liquids more economically and with lower emissions than any other burner. Even contaminated oils and biogenic fuels are no problem for the ROTONOX GL and underline the strength of the robust design. The rotary atomiser technology offers maximum reliability with optimum burnout, very low emission values and an enormous longevity.

Technical information

Burner capcity:

1 – 45,3 MW

Fuels:

Natural gas, liquid gas, hydrogen, biogas,fuel oil extra light, fuel oil heavy, bio oil, animal fat, special oils and other alternative liquid and gaseous fuels

Applications:

Shell boiler as a three-pass boiler, water tube boilers, thermal oil heaters, hot gas generators / combustion chambers

Industries:

Energy and heat supply, chemical industry, food industry, steel and metal production, building materials industry, wood processing

Benefits

- Reprocesses even super-heavy oils and the most difficult fuels and waste materials reliably and with low emissions

- Suitable for almost all heat generators and combustion chamber geometries

- Robust, modular design based on 1000-times proven rotary atomiser technology

- Simultaneous combustion of several gases and oils

- Very wide control range for liquid and gaseous fuels

- Low fuel supply pressure and low preheating temperature required

- High efficiency, low maintenance costs and long service life

- Conforms to European directives and regulations of ship classification societies

- Uncomplicated installation and commissioning

- Unrivalled burner flexibility

- Version for air preheating (optional)

- Integrated combustion management system (optional)

- Further modular system extensions possible (optional)

© SAACKE GmbH 2024