Burner / Steam pressure atomizer - Equipment of a district heating plant near Vienna with burners for low NOx emission and flexible operation

Unique in Europe in this magnitude

The utility company Wien Energie GmbH operates Austria’s largest district heating grid. For the construction of a new peak load plant to supply 70,000 households in the center of Vienna, the operator decided to ensure even better compliance with the strict emission requirements in order to remain well-equipped for the future reductions of the associated legislation. The new construction on the historic site of the Vienna Arsenal is equipped with a maximum firing rate of 360 MW. The plant engineer ANDRITZ AG commissioned SAACKE GmbH to install twelve DDZGG-LN steam pressure jet burners. The burners not only fall below the emission requirements, they also enable flexible fuel operation.

“The SAACKE burners ensure that our customer is well-equipped for the future. They fall well below the strict requirements specified by the Austrian emissions law EG-K 2013"

- Nikolaus Dobrowsky, Project Manager, SAACKE GmbH

From trial to emergency operation: reliability of supply 100% guaranteed

The combination of the high firing rate, low emissions and flexible fuel operation is unique in Europe on this scale. The tight schedule, which provided for an integration into active operation, was a challenge: the commissioning phase and the trial operation were scheduled for the main operating period between January and March. The generated quantities of heat had to be coordinated with the district heating grid. Since the heating station acts as a reserve in case of failure of other heating plants, the operator also required a run-up time from standstill to full load operation of within 30 minutes. This requirement was tested in an emergency operation during the trial period, but posed no problems for the SAACKE burners.

All benefits at a glance

- Low NOx technology for low emissions well below the national and European emission standards

- Optimized and flexible use of different fuels for each boiler

- Higher efficiency due to the high control range for oil and gas combustion

- Increased economy and optimized efficiency due to individual burner control, low air excess and low flue gas recirculation volumes

- Low maintenance costs and long service life

The SAACKE solution in detail

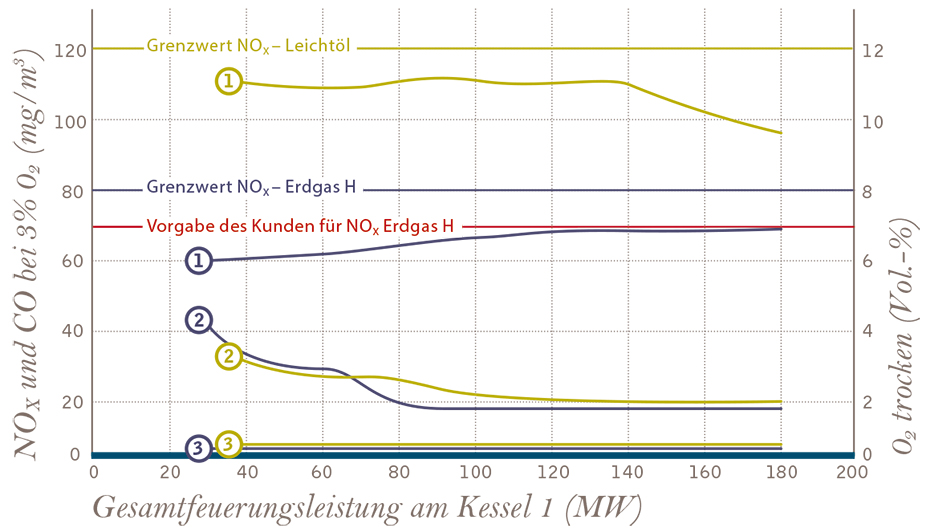

The two hot water boilers were each equipped with six DDZGG-LN burners, each with a max. firing rate of 30 MW, and are controlled by an individual burner control system. Light fuel oil (LFO) and natural gas H can be used simultaneously or independently, which enhances the flexibility for the operator. A high control range of 1:6 in gas mode and 1:5 in oil mode, low excess air and a low flue gas recirculation volume ensures economical and efficient operation. The order volume included the burners as well as gas and oil supply/control, burner safety technology, ignition and cooling air supply for the burners and boilers, commissioning and service beyond the conclusion of the project.

The burners are designed for 72h operation without constant monitoring in accordance with the Austrian law on the operation of steam boilers (ABD-V).

Compliance with the defined limit values and comprehensive service during commissioning and operation were essential for successful project implementation. The DDZGG-LN provides optimal cost-effectiveness. In the meantime, the DDZG(G)-LN burner series has been further developed and replaced by the SAACKE ATONOX.

MORE INDUSTRY REFERENCES

- Plant modernization - Conversion from mixed firing to natural gas in specialty chemicals

- Alternative Fuels - Lean gas

- Alternative Fuels – Molasses combustion in Brazil

- Water tube boilers - Modernization of a refinery in Bulgaria

- Shell boilers - Combined heat and power system incl. gas turbine exhaust gas burner and control technology for food production

- Drying processes - Pulverized fuels and biogas for drying sugar beet cossettes

© SAACKE GmbH 2024