Water-tube boilers

Increasing efficiency and best emission values

Water-tube boilers are used in a wide variety of industries, such as energy and district heating supply or the paper industry. In the 30 to 40 year service life of a boiler plant, the burners have to be modernized several times in order to comply with current emission regulations, especially for NOx. Consequently, the following applies to both new plants and modernizations: Low NOx firing technology at the latest state of the art is an absolute must and its operational reliability is maintained.

For water tube boilers, SAACKE offers individual burners as well as fittings, burner controls and complete solutions. At SAACKE, you will find the right products and services for a new plant or for the modernization of your existing plant. All these offers aim at making your water tube boiler firing system as efficient and low emission as possible.

The SAACKE portfolio includes:

- Burners and combustion systems for standard and special fuels, such as lean gas, converter gas or molasses

- Burners and combustion plants with minimum NOx emissions (e.g. for ultra-low NOx emissions)

- Support and start-up burners for fluidized bed boilers (e.g. for waste to energy plants)

- Modernization of existing boiler plants by installing new burners and/or further modernization measures

MODERNIZATION OF A REFINERY IN BULGARIA - EMISSIONS SIGNIFICANTLY LOWER THAN SPECIFIED

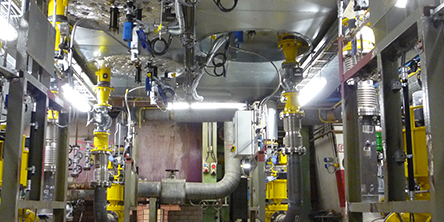

On Bulgaria's Black Sea coast, the Russian oil company Lukoil operates the largest refinery in Southeast Europe. During the refining of crude oil, refinery gas is a by-product of the process, which has not been used efficiently so far. Until now, the boilers have operated inefficiently and achieved emission values around 350 mg/m3 NOx. SAACKE developed an intelligent modernization concept for the firing plant with the help of ultra-modern CFD (Computational Fluid Dynamics) flow simulations. This concept could be optimally integrated into the existing infrastructure and led to a very short rebuilding phase as well as significantly reduced rebuilding costs.

► More about this project

© SAACKE GmbH 2024