- SAACKE 100 % hydrogen burners ensure conversion from natural gas to fuel of the future in paint drying and boiler house

- Commissioning of the first pilot plant as part of the GREEN DAY.

Bremen / Leipzig, October 27, 2022 – Last Thursday, an important milestone on the way to decarbonizing the production of the future took place at the BMW Group plant in Leipzig: At the so-called GREEN DAY, the automobile manufacturer presented, among other things, the potential of hydrogen as an energy carrier as a substitute for fossil fuels using concrete projects in production and logistics. Burners from the combustion specialist SAACKE GmbH in Bremen, Germany, which is one of the few suppliers on the global market capable of processing 100 % hydrogen, play an important role here. As part of the GREEN DAY, the first burner was converted live from natural gas to hydrogen in Leipzig.

Easy H2 conversion thanks to decades of experience

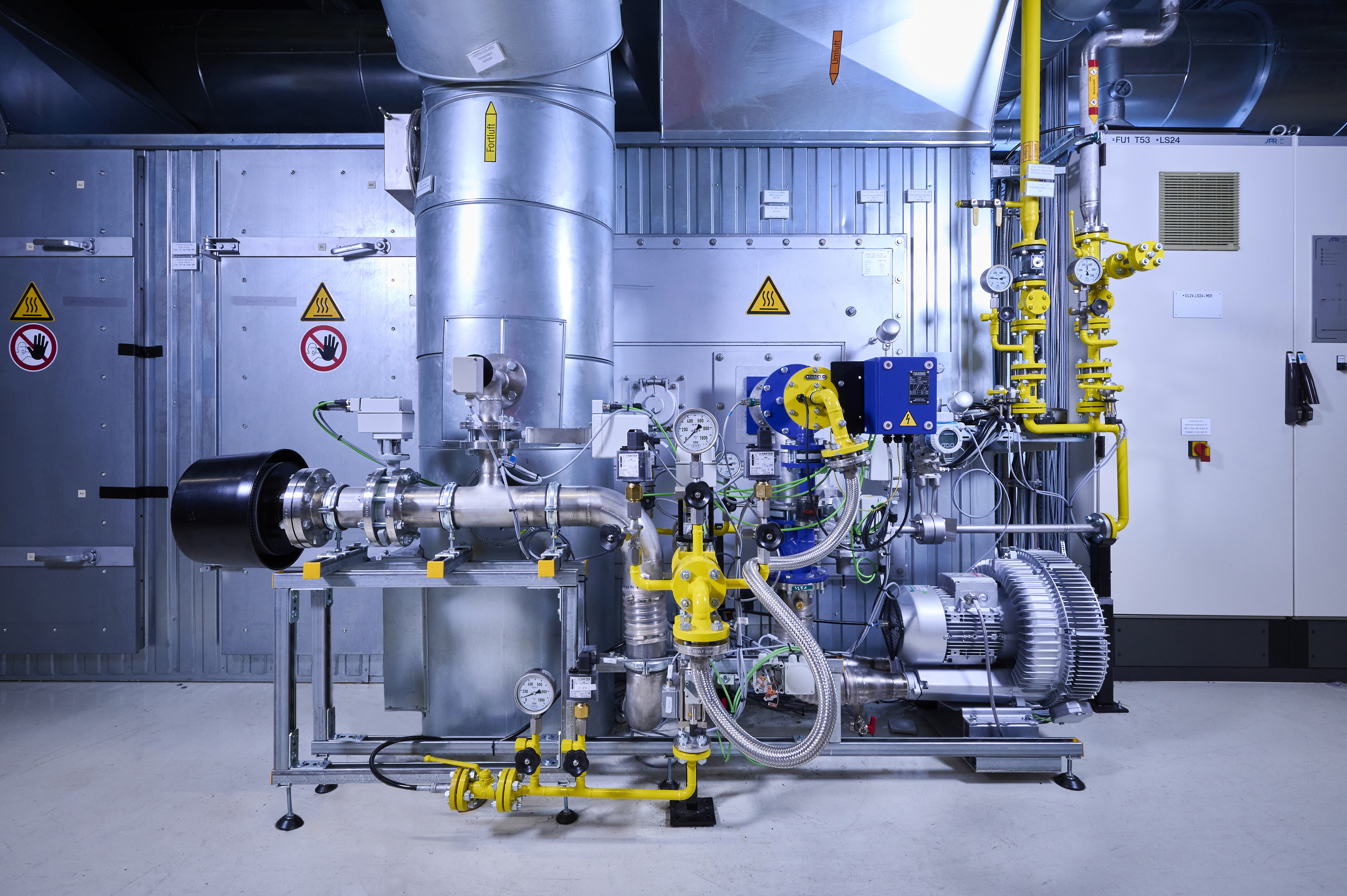

The modern combustion technology with an output of several 100 kilowatts is to be used in the paint drying line as well as the thermal afterburning system and ultimately also in the boiler house. "SAACKE benefits here from decades of experience in the development and manufacture of hydrogen burners and was therefore able to convert proven combustion systems of the SSBG micro type to H2 operation and the significantly smaller output range, which deviates from the usual portfolio, with little effort," explains Dr. Ronald Wilhelm, SAACKE project manager in the product management department. "This makes us the first in the world to have developed an H2 burner in this small output size and shows once again that green heat is feasible."

That's why the entire industry is also looking intently at the "green factory" pilot project launched by BMW, because in principle the technology could be used in all automotive plants. "BMW in Leipzig commissioned us in 2021, and within a few months we developed a burner that is precisely tailored to the requirements on site," reports Martin Gerspach, head of thermal process plants at SAACKE. "Over the next few years, more H2 burners will be successively installed at the site."

Decarbonization of production

The topic of CO2-free manufacturing is becoming increasingly relevant worldwide in light of climate change and pressing sustainability issues, and is forward-looking for the ecological transformation of the economy. The BMW Group's vision is to decarbonize production in Leipzig. One way the automobile manufacturer is achieving this is by replacing fossil fuels with green hydrogen as an energy carrier. Green heat contributes to this with the help of SAACKE hydrogen burners. In addition to the aspects of sustainable heat generation, logistics and mobility at the plant, the infrastructure in the surrounding area is also being adapted. For example, a hydrogen pipeline is also being planned that will supply the plant with green hydrogen over the next few years.

SAACKE GmbH specializes in thermal processes and plants in the industrial and maritime energy management sector and is one of the world market leaders in this field. The medium-sized family business was founded in 1931 and employs a total of around 1,000 people, including a good 400 engineers and technicians. It has production sites in several countries as well as a worldwide service and sales network. Headquarters and research and development are located in Bremen, Germany.

For technical questions and further company information please contact:

SAACKE GmbH

Contact: Margit A. Hendricks

Südweststraße 13 • 28237 Bremen

Phone +49 421 - 64 95 5340

Email: m.hendricks[at]saacke.com • www.saacke.com

For press inquiries please contact:

DIALOG Public Relations

Contact: Bastian Korte

Am Markt 1 • 28195 Bremen

Phone +49 421 - 32 88 11-21

Email: Bastian.korte[at]dialog-pr.com