SAACKE gas duct burner LONOX DTEG combines the latest technology with maximum efficiency

In many places, plant operators are trying to better utilize resources and increase the degree of fuel efficiency. A popular step to increase efficiency is combined heat and power (CHP) generation. The catch: combustion engines, such as gas turbines with downstream heat recovery, generally have an overall efficiency of < 75%. Yet exploiting unused potential is currently more important than ever. Due to an implementation decision of the EU Commission, operators of large combustion plants are facing additional challenges: with the expiration of the implementation period in 2021, country-specific emission requirements and associated subsidies will no longer apply. Instead, the determining factor will be the application of the best available technologies on the market. This intensification of the legal situation signals a true paradigm shift for many industrial sectors. CHP generation plants will also be affected by this new regulation.

Overall degree of efficiency of over 90%

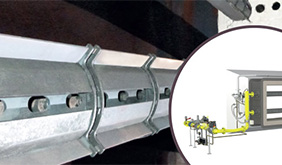

That is exactly where SAACKE focusing its efforts with its technological solution of the LONOX DTEG gas duct burner – an auxiliary firing system with outstanding flame stability for the use of turbine gases in combined heat and power generation. It increases plant efficiency through the reduction of the residual oxygen content in the exhaust gas and leads to an increased degree of efficiency of the entire plant in excess of 90%. The advantages of LONOX DTEG at a glance:

- NOx emissions approximately 10% below the level of other competitors

- Modular construction: individual bars or frames with multiple bars are available for delivery as required. No welded constructions in the flame zone, so that thermal stresses can remain as low as possible

- Intelligent design for high flexibility with individual adaptations (including option of bar shut-down to expand the control range compared to a traditional CHP generation burner)

- User-friendly maintenance and long product life cycle

- In-house CFD analyses by SAACKE to optimize the flow distribution and reduce pressure losses

Learn more about LONOX DTEG gas duct burner >>

SAACKE customer day in the Elbphilharmonie – positive feedback

To provide competent and neutral information for all operators of combined heat and power generation plants about the subject of the best available technologies, SAACKE invited specialists, customers and interested parties at the end of November 2018 to the Hamburg Elbphilharmonie. The concept of the free one-day event at "The Westin" (Marriott Hotel) consisted of expert lectures as well as an excursion to an industrial CHP generation plant at the ADM Archer Daniels Midland Company, which already today, thanks to a SAACKE gas duct burner, fulfils the EU requirements of tomorrow with NOx values below 25 mg/MJ. “The EU confronts plant operators with many new developments and challenges. The idea behind our event was to increase awareness of this topic for decision-makers in companies, offer orientation and provide answers to pressing questions,” explained Dipl.-Ing. Horst Wrissenberg who is active in SAACKE Process Engineering. “This seems to have been successful: The feedback from the expert group of participants was consistently positive, as were the discussions held on at least one concrete project,” he looks back. “We therefore feel encouraged to continue this format for a competent communication on emission topics and the technological further development of combustion plants. Because one thing is clear: 2021 is not far away any more.”